Level 1 Faults:

Detected issues at the string and combiner level, impacting 4,760 panels in total (800 panels in strings and 3,960 in combiners).

Level 2 Faults:

Involved 7,200 panels affected by tracker misalignment, leading to potential energy losses.

Level 3 Faults:

Hotspot and diode issues were identified on 142 modules, which could lead to further degradation if not addressed promptly.

Challenge

The client was facing potential underperformance due to suspected panel faults, but lacked precise data on the scale and exact location of the issues across their site. A traditional ground-based inspection would have taken significant time and resources, making it inefficient for a site of this size.

Solution

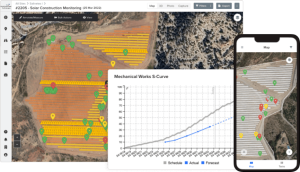

Horizonview Technologies deployed our high-resolution infrared-equipped aircraft to perform a full aerial scan of the site. The flight took just over an hour to cover all 204,480 panels, leveraging our advanced fault detection system.

Our technology enabled us to quickly and accurately identify 227 distinct faults affecting 12,102 panels—roughly 5.92% of the total installation. These faults, if left unresolved, would have led to an estimated loss of over 10 million kWh of energy annually.

Total Panels on site: 204,480

Total Faults detected: 227

Panels Affected: 12,102

Percent of site affected: 5.92%

Estimated Annual Energy Loss: 10,235,286 kWh

Estimated Annual Loss:

$314,117

227 faults detected

12,102 panels affected (5.92%)

~10.2M kWh estimated annual loss

In just over an hour of flight time, Horizonview identified faults that could have cost millions in lost production.

Merced 105 MW Solar Farm – 227 faults detected – 12,102 panels affected (5.92%) – ~10.2M kWh estimated annual loss In just over an hour